UNAVCO offers borehole services to the scientific community including advice on instrument siting, permitting, drilling, installation, data collection and analysis. The suite of instruments UNAVCO installs includes tensor strainmeters, 3-axis seismometers, pore pressure sensors and tiltmeters. As part of the Network of the Americas (NOTA), UNAVCO has a wealth of experience in drilling, installing, and operating borehole instruments in different tectonic environments for one of the largest borehole strainmeter networks in the world. For example, the NOTA borehole network has recorded episodic tremor and slip (ETS) signals in the Cascadia subduction zone, volcanic unrest on Mount St. Helens and Yellowstone, aseismic deformation along the creeping section of the San Andreas and in the Anza seismic gap to study the transfer of stress between faults.

Selection of the site and target installation zone within the borehole are critical factors in ensuring a successful installation. Permitting, power requirements and access are all factors that must be considered in addition to the scientific outcomes that are sought. Of particular importance for strainmeter installation is the choice of grout and the procedure by which the instrument is installed in the grout as strong bonding of the strainmeter to the surrounding rock is required to attain a high-quality data set. UNAVCO can assist researchers by providing the engineering expertize and the equipment required to select a suitable site, construct a reliable power source, drill the borehole and then determine the best installation zone within the hole using logging data. After instrument installation, UNAVCO will set up data flow from the on-site data logger to a data center archive and provide guidance on the maintenance required to keep the site on-line. In addition to installation and operation, UNAVCO provides instruction on how to process and interpret borehole data sets via short courses, workshops and individual training.

Siting

Borehole strainmeters are sited in groups of four to eight instruments to image a target geophysical process. These arrays are typically designed based on geophysical models of the target process, for example tectonic or volcanic deformation. While idealized locations are easy to predict and, in some cases obtainable, the most difficult aspect of borehole strainmeter site selection is finding a site with a section (10-20 ft) of competent, unfractured rock 450-800 ft below the surface. The basic selection criteria used to identify a good strainmeter site are:

- Competent unfractured rock at a depth of 450 ft to 800 ft

- The absence of fracture zones through which water may be flowing

- Low probability of nearby pumping which may disturb the local strain field

- A well drained surface site to avoid flooding

- Secure from any possible vandalism

- Access to power and telemetry

Based on these selection criteria, the Network of the Americas developed the following list of guidelines to assist in determining the viability of possible borehole strainmeter sites.

- Geophysical Importance

- Geology

- Rock Quality

- Proximity to Wells

- Topography

- Seismic and Cultural Noise

- Sky View for Telemetry and GPS

- Solar

- Access

- Relative Location to AC Power

- Security

Geophysical Importance

This refers to how well a prospective site fits into the proposed array of instruments. Some sites may be more important in an array design due to their ability to image the target process or operate in conjunction with other geophysical instrumentation.

Geology

Rock type is important for strainmeter sites. Ideally, the rock would have identical properties as the strainmeter sensor, but in the real world this is not possible without designing each instrument to match the rock in each individual borehole. The preferred rock type would be a granitic rock type due to its hardness and massive non layered characteristics. This would be a crystalline rock with a hardness of 5-6 (Mohs hardness scale). In practice, igneous, metamorphic, and sedimentary rock are all possible. The array design and possible rock types available in a region may require compromise in the overall array design.

Rock Quality

This refers to rating the quality of rock based on surface outcrops and/or well logs. Rock type, hardness, presence of fractures, and defined lineations are all features to note. The vertical thickness of competent sections and the inclinations of any layers or bedding planes etc are also to be noted. The more hard and massive a formation, the more desirable it is. Ideally, we would use massive, unfractured intrusive granites. Often, however, we must use rocks with layering such as sandstones, or metamorphic foliations like gneisses. Layering that is more horizontal is more desirable. Steeply dipping beds or vertical fractures are less desirable.

Proximity to Wells

Active pumping of water wells near a strainmeter site may be detected in the strainmeter data. These effects will vary depending on properties of the aquifer being pumped and the well proximity. Strainmeter sites should not be located near any actively pumped wells. Any wells near potential sites should be noted by distance and size of well pumps.

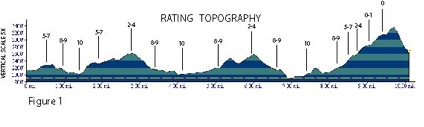

Topography

Certain topographical effects may cause noise in deformation data. The preferred site would be on level ground in the middle of a plain. This is not always possible. The worst location would be on the top of a steep narrow ridge. See figure below for a topographic rating profile. Location of strainmeter sites should be at least 100 m from any streams.

Seismic and Cultural Noise

Strainmeter sites should be selected away from (>1.0 Km) signifigant highway noise and/or railroad tracks. Other cultural noise sources should be avoided, some example would be water tanks, reservoirs, wind generators, quarries, land fills or anything which causes vibration or surface loading near a potential site. Despite cultural noise concerns, stations may often be sited near quarries in heavily wooded areas, where a quarry is a sure way to tell that there is near-surface rock of a suitable type.

Sky View for Telemetry and GPS

This relates to possible telemetry links (radio, satellite dish etc) and co-located GPS receivers. Open sky view 15 degrees above the horizon is good. The view to the south is more critical than the north, as that is where most satellites orbit. Measure the angle above horizon in the geographical directions (N, NE, E, SE, S, SW, W, & NW) plus the direction and angle of least amount of sky view.

Solar

How well the site is suited for solar power. Base this on the amount of southern expose and the number of hours of direct sunlight during a typical winter day. Trees, mountains, and buildings may all degrade the amount of sunlight.

Access

Conditions of the access into and the working space at a potential site. The drilling of a borehole for strainmeter installation requires access with large heavy equipment (10-20 ton vehicles). Access routes must be capable of supporting these vehicle weights and steep grades, side hill angles, and turning radius are importance considerations. If access is on dirt roads there may be different concerns based on dry and wet conditions. Any locked gates can be issues with multiple personnel accessing the site. Access would also include the space at the site suitable for a drill rig and all support equipment. The minimum space would be 30 ft X 80 ft and the preferred space would be at least 100 ft X 100 ft. The working space should be relatively level (< 3 ft of grade in 80 ft).

Permitting

After a suitable site has been located, proper permits must be obtained. Permits for borehole strainmeters can be complicated, costly and require extensive time. Some permits will require lengthy processes like public notification and input. There are many permutations of what is needed depending on location with political units such as counties, cities and states. Typical permits may include:

- Land Use Permit – Always required

- Drilling Permit – Always required and typically obtained by a licensed driller

- Construction Permit – depends on location and local regulations

- Environmental Impact Statement – highly depends on land owner (Federal) and relative location to cultural resources

- Special Environmental – For example any possible disturbance of the water table in the Lake Tahoe water district requires an extensive permit with public input.

Drilling

Drilling is the most costly and difficult control aspect of installing a borehole strainmeter. The Network of the Americas, drilling over 125 holes during the construction phase, gained valuable skills in developing Statements of Work, Drilling Plans, Contracts and management of drilling operations. Costs for a borehole during the construction of the Network of the Americas ranged from 33K to over 200K. Many factors go into designing and drilling a hole.

Selection of Driller

The installation of a borehole strainmeter requires highly competent drillers and modern drilling equipment. Identifying these drillers and developing a working long term relationship with them is a time consuming and difficult task.

Development of a Statement of Work and Drilling Instructions

The Statement of Work is critical. This document will allow you to choose only competent drillers in the contracting process through detailed specification of equipment and drilling experience required. This document also outlines critical choices for cost control, for instance coring the target installation zone is highly desirable but can be extremely costly if done incorrectly. Verticality of the hole is a requirement of the strainmeter installation and requires the use of centralizers and experience drillers.

Management

Even with a perfect contract and competent drillers, the drilling phase of the operation requires active and intense management. The decision making process must be done on-site and in real-time with outcomes that can directly impact the cost and success of the borehole.

Home

- Borehole Instruments

- Last updated: 23 June 2021