Borehole instruments are grouted in place 100 to 250 m below the surface to operate at the low noise levels required to capture small, short term transients.

Borehole Strainmeters

Borehole strainmeters (BSM) measure very small changes in the dimension of a borehole at depths ranging from 100 m to 250 m. This is accomplished by measuring the change in diameter or volume of a strainmeter installed in the borehole.

The GAGE Facility uses a instrument developed and constructed by GTSM Technologies which measure the change in borehole diameter along three azimuths separated by 120 degrees perpendicular to the borehole. Strainmeters can detect changes in the diameter of a borehole on the order of four picometers, about one ten millionth of the width of a human hair and smaller than the width of a Hydrogen atom. A change of four picometers along the ten cm width of the strainmeters equates to approximately 0.05 nanostrain while signals of geophysical interest range from several nanostrain to many hundreds of nanostrain. For example the strains induced by earth tides, the effect of the Sun and Moon on the Earth’s crust, are ten’s of nanostrain.

The Gladwin tensor strainmeters (GTSMs) have a precision of 1 part per billion over short periods. The GTSM uses differential capacitive plate transducers to measure change in the borehole diameter. As the borehole deforms the plates move relative to each other causing a change in capacitance proportional to the change in distance. The GTSM has three strain gauges oriented 120 degrees apart. The independent measurements of change in length along each axis can be combined to obtain three other strain components that describe the horizontal strain tensor: the areal strain, and gamma 1 and gamma 2 shear strains. Each gauge is contained in a separate module about 10 cm in diameter and the three modules are stacked above each other within the strainmeter. The entire instrument is about 254 cm long and weighs 50 kg. The instrument is grouted into the borehole using an expansive grout to ensure it is always under compression.

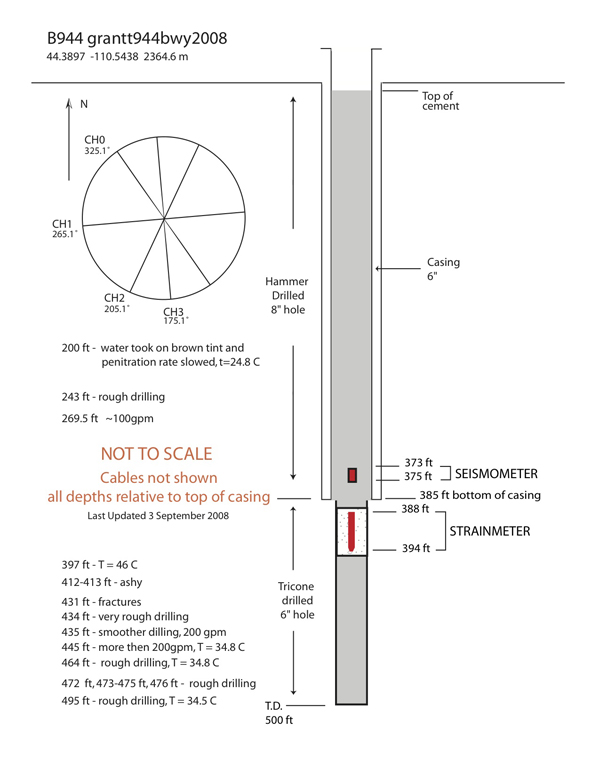

A typical installation starts with a borehole that is 15 cm in diameter and approximately 200 m deep, the actual depth depends on the location of desirable rock. A strainmeter is installed at the bottom of the borehole with specialized expansive grout. A seismometer is then installed from three to ten meters above the strainmeter. The upper portion of the borehole is used for auxiliary instruments such as: pore pressure transducers, tiltmeters and continuous thermal measurements. In total the borehole network contains nearly 300 instruments and produces close to 1800 channels of data.

From a science perspective, the strain meter array was designed to study the three-dimensional strain field in the western United States that results from deformation across the active boundary zone between the Pacific and North American plates. The GAGE Facility Borehole Strainmeter Network augments the knowledge of this strain field.

Borehole Seismometers

The GAGE Facility installed and maintains more than 70 borehole seismometers as the NOTA Borehole Seismic Network with sites located from Vancouver Island to Southern California, including Yellowstone. Most borehole seismometer installations in this network are co-located with borehole strainmeters, but a few are stand alone. The sensors are Sonde-2 seismometers. This sensor uses three 2-Hz geophones in a tri-axial configuration. Eight sites in the Anza, California region also utilize a type of microelectomechanical system (MEMS) accelerometer, again, three in a tri-axial configuration. A borehole seismometer unit installed at a proper depth allows for the detection and location of microseisms that can be missed by a surface seismometer. The data set generated by the NOTA Borehole Seismic Network has become an integral component to research being done in regional seismic networks, such as those in Anza, California, and Yellowstone National Park.

Borehole Pore Pressure Sensors

A pore pressure senor is an in-situ device designed to measure fluctuations in groundwater pressure. The purpose of the pore pressure sensors is to help characterize the hydrological response of the site at time scales of seconds to years.

For example, twenty-three pore pressure sensors were installed in the Anza, Parkfield and Pacific northwest strain meter arrays as part of the Network of the Americas (NOTA). All are co-located with NOTA strainmeters and seismometers.

Borehole Tiltmeters

A tiltmeter is an instrument designed to measure very small changes from the horizontal level, either on the ground or in a borehole. In the geosciences tiltmeters are used extensively for monitoring volcanos, the response of dams, potential landslides, and the orientation and volume of hydraulic fractures. Twenty-six borehole tiltmeters were installed during the construction of the Network of the Americas, all located on volcanoes in Alaska, Mt St Helens and Yellowstone. These instruments, manufactured during the NOTA construction phase by Applied Geomechanics and now by Jewell Instruments, are capable of resolving changes in tilt on the order of 5 nanoradians.

Home

- Borehole Instruments

- Last updated: 22 August 2023